ballbearian

Veteran Member

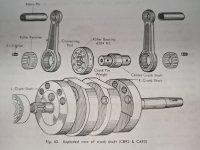

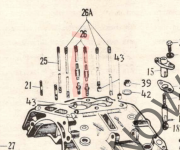

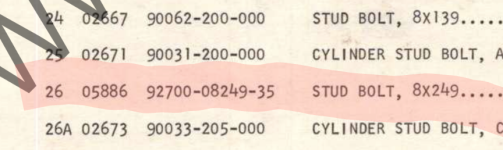

In the pic below that, it looks like the bronze bushing for that end is turned and maybe didn't get its splash feed of oil in the catch slot. Usually a knock pin is there to keep it oriented with the slot up. I'd look at the bore of that bush. Hopefully it'll clean up and that small end of the shaft.The small end of the counter shaft appears blackened like loss of oil pressure/feed.

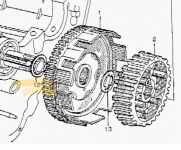

That seems common to have the knock pins incorrectly seated, or missing, or not having hollow ones in the right place. Same with the bearings that have the half ring retainers.

Overall, it looks really good, compared to the 160 and 150 I've been into.

If you push down slightly on the windage trays, those pins slide out and then you can really clean out the sump area.

Now you can really clean the crank sludge traps and oilways to the big end of the con rods.

Last edited: