-

Don't overlook our Welcome Package, it contains many links to important and helpful information about functions at VHT like posting pictures and sending PMs (private messages), as well as finding the parts you need.

AD

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rickman CL175…a true Metisse!

- Thread starter Jays100

- Start date

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Modern forks, that bike won't know how to act!

Jays100

Veteran Member

Still waiting for shocks and front spokes, next week maybe.

Jays100

Veteran Member

Hopefully an improvement, ha!

Have to finish the rear hub, it has 50 yrs of accumulated and hardened yuck. Had to use a file as a scraper on some of it. Once that’s done, I can start lacing and truing. Mama not gonna be happy when I take over the living room on icky weather days. Still, she is used to my ways, sorta, and I’ll pay later. Life’s good.

Have to finish the rear hub, it has 50 yrs of accumulated and hardened yuck. Had to use a file as a scraper on some of it. Once that’s done, I can start lacing and truing. Mama not gonna be happy when I take over the living room on icky weather days. Still, she is used to my ways, sorta, and I’ll pay later. Life’s good.

Jays100

Veteran Member

This build is quasi inspired by what Steve built for his granddaughter. Our latest is 8mos old so I’m starting early.

Jays100

Veteran Member

Jays100

Veteran Member

crazypj

Veteran Member

- Joined

- Jun 5, 2020

- Total Posts

- 1,015

- Total likes

- 405

I was going to comment on the stupid tyre size fitted but I see your already on itGood Grief, I hadn't realised that those Mutt atrocities had made it across the pond. Assembled in Birmingham UK from Chinese parts, selling 125cc bikes on Chinese knobbly tyres to inexperienced youngsters, recipe for disaster on cold wet UK tarmac. Thoroughly nasty things, again just IMHO.

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

Jays100

Veteran Member

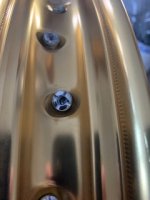

Eggnog? I mean, it's a bit early for scotch.One more because they’re pretty and we like nipples.

Jays100

Veteran Member

Coffee, and 3in1 oil.

Have switched to dihydrogen monoxide, er, H2O, hitting the hard stuff baby!

Have switched to dihydrogen monoxide, er, H2O, hitting the hard stuff baby!

ballbearian

Veteran Member

DT spokes? If so they're nice.Front was more dramatic but the spokes were from Sweden and beautiful quality.

View attachment 27195

Jays100

Veteran Member

Well, both rims are from Thailand as is the rear spoke set - they’re plated steel and fit well.

The front spokes are from Sweden and are stainless steel. Cross-center.com

Quality of it all is very good.

Each wheel weighs 8.5lbs, bare as shown (without rubber, brakes, axles).

The front spokes are from Sweden and are stainless steel. Cross-center.com

Quality of it all is very good.

Each wheel weighs 8.5lbs, bare as shown (without rubber, brakes, axles).

ballbearian

Veteran Member

Nice. I want to get building on my alloys for the 160. Good winter project inside.Well, both rims are from Thailand as is the rear spoke set - they’re plated steel and fit well.

The front spokes are from Sweden and are stainless steel. Cross-center.com

Quality of it all is very good.

Each wheel weighs 8.5lbs, bare as shown (without rubber, brakes, axles).

Jays100

Veteran Member

Jays100

Veteran Member

bilbikek411

Veteran Member

A solid set of forks;What brand are they ?View attachment 27489Some progress, head bearings in and triples mounted. Some adjustment still needed but the heavy work is done.

Jays100

Veteran Member

Jays100

Veteran Member

The forks are sourced from China, through a US importer…I think.

I mentioned in an earlier post that finding a nice, useable (I.e. good chrome) set of used forks was stupid money. Found these on eBay, along with shock absorbers and here we are. Forks and shocks (fully adjustable I might add) for less than a bad set of mini Ceriani MX.

Front Forks Shock Triple Tree Clamp For Dirt Pit Bike 110cc 125cc 29" 45/48mm | eBay

Features: · 100% brand new and high quality,Durable. · It could correctly replace the original quality part. Specification : Front Fork Suspension: Length : 73.66cm(29") Fork diameter : 48mm/(1.89") Handlebar Triple Tree Riser Clamp : Total Center pole : 240mm Center pole diameter : 22mm Bolt...

www.ebay.com

I mentioned in an earlier post that finding a nice, useable (I.e. good chrome) set of used forks was stupid money. Found these on eBay, along with shock absorbers and here we are. Forks and shocks (fully adjustable I might add) for less than a bad set of mini Ceriani MX.

Owww.And the associated cost of said progress.

View attachment 27491

I am not familiar with the frame name and this is my first time hearing about the material and design parameters. With your title Jay I thought it was an "Old Masters" piece of artwork. Once your finished, I see it will be that and more with the new forks and rims your already adding! I will assume the pistons and rings are for this build? Hopefully they will work for you and looking forward to your the progress on the bike.

Here's a bit of historyI am not familiar with the frame name and this is my first time hearing about the material and design parameters.

Our Heritage

Richard Pitman

Veteran Member

It does. Man, a 4 valve head for the 450 would be nice.

crazypj

Veteran Member

- Joined

- Jun 5, 2020

- Total Posts

- 1,015

- Total likes

- 405

Piper made a 4 valve head for 350 in the 1970's.

It was still in their catalogue in 1977 but I have no idea what happened to mine? (catalogue not head)

It was still in their catalogue in 1977 but I have no idea what happened to mine? (catalogue not head)

Jays100

Veteran Member

More plunder!

Not quite to gizmos and gadgets yet but progress just the same … and hiding my spending.

Not quite to gizmos and gadgets yet but progress just the same … and hiding my spending.

bilbikek411

Veteran Member

would make a nice hot rodI thought that I was reasonably well informed, but that 'Adelaide' engine is one I'd never heard or read about, amazed that I've not seen it mentioned in the classic bike magazines.

Reminds me of a Honda design !

View attachment 27556

Jays100

Veteran Member

Jays100

Veteran Member

Happy New Year ya bunch’a knuckleheads! I’m glad to know ya.

Had time over the holidays to find a way to spend more money. So, I bought a wheel truing stand. To true my wheels I’m approaching this legitimately - something I’ve never done, always making do with an axle clamped in a vice and some shaky pointer, indicator mount or some such. I embarrass myself and my profession.

I put together this low cost item (how bad can it be?) thinking I can “true” my wheels 36 ways in 3 dimensions to arrive with wheels that spin true and accommodate any errors of pitch, roll and yaw. It turns out after two hours of fiddling per wheel that 1/16” (1.5mm) runout is the best these rims can deliver.

The fixture axle shaft has .015” runout which doesn’t help anything either. The good thing is the whole thing is rigid enough that manhandling the wheels/spokes doesn’t adversely affect my indicator mounting. Really I had the spokes tight and within the 1/16” in 30 minutes but chased my tail and other adjustments to marginally improve.

My take away is it’s a dirt bike for crying out loud, sheesh. Don’t get yer knickers in a knot is my self talk.

Had time over the holidays to find a way to spend more money. So, I bought a wheel truing stand. To true my wheels I’m approaching this legitimately - something I’ve never done, always making do with an axle clamped in a vice and some shaky pointer, indicator mount or some such. I embarrass myself and my profession.

I put together this low cost item (how bad can it be?) thinking I can “true” my wheels 36 ways in 3 dimensions to arrive with wheels that spin true and accommodate any errors of pitch, roll and yaw. It turns out after two hours of fiddling per wheel that 1/16” (1.5mm) runout is the best these rims can deliver.

The fixture axle shaft has .015” runout which doesn’t help anything either. The good thing is the whole thing is rigid enough that manhandling the wheels/spokes doesn’t adversely affect my indicator mounting. Really I had the spokes tight and within the 1/16” in 30 minutes but chased my tail and other adjustments to marginally improve.

My take away is it’s a dirt bike for crying out loud, sheesh. Don’t get yer knickers in a knot is my self talk.

Jays100

Veteran Member

And Happy New Year to you too, we're knucklehead brothers.Happy New Year ya bunch’a knuckleheads! I’m glad to know ya.

Exactly. While it's unlikely you'd ever feel that on a street bike, it's a guarantee you won't on a dirt bike. Even one with a heavy twin cylinder 4 stroke 175 engine.My take away is it’s a dirt bike for crying out loud, sheesh.

bilbikek411

Veteran Member

Jay,is that a static wheel balancer ?

What brand is it ?

What brand is it ?

Richard Pitman

Veteran Member

Looks very similar to the one I've got, generic Ebay / Amazon item.Jay,is that a static wheel balancer ?

What brand is it ?

Jays100

Veteran Member

An eBay purchase, I was looking for a low cost better way to support the wheel. My indicator stands are all magnetic so it also had to be steel. Cost was $45 with shipping included and I’m generally happy with it. I dont build wheels all that often any more but when it is needed, the stand is a much nicer tool.

kbongos

Veteran Member

They look very asymmetric

Jays100

Veteran Member

There is another thread on wheel building where they talked about symmetric and asymmetric or offset wheels. For this build I won’t have that problem as I have not fit or aligned the wheels into the frame. That is, the wheel spacers.

To be sure, perfect alignment isn’t required, it’d be nice, but not required. Some years ago frame designer/builder Rob North built factory race Triumph Trident frames with what I was told some 1/2” offset in the wheel track. (This was from Aussie racer and frame builder Kelvin Franks at his shop in Anaheim) The result was the bikes turned ever so slightly better one way over the other and the riders adapted accordingly, and still won races.

To be sure, perfect alignment isn’t required, it’d be nice, but not required. Some years ago frame designer/builder Rob North built factory race Triumph Trident frames with what I was told some 1/2” offset in the wheel track. (This was from Aussie racer and frame builder Kelvin Franks at his shop in Anaheim) The result was the bikes turned ever so slightly better one way over the other and the riders adapted accordingly, and still won races.

Last edited:

Jays100

Veteran Member

Has anyone used a combo tach/speedo gauge from AliExpress?

Looking at this: https://www.aliexpress.us/item/3256...hpYiLLdE&utparam-url=scene:search|query_from:

The original Metisse Micro used a speedometer/odometer for enduro's and street use. I'm vascillating between the above, and this one:

As you can tell, my requirements revolve mostly around cost as building a bike from scratch iskinda really spendy. Still, found a useable gas tank for a really good price, should arrive next week (it was so good I used Craigslist out of my area).

Looking at this: https://www.aliexpress.us/item/3256...hpYiLLdE&utparam-url=scene:search|query_from:

The original Metisse Micro used a speedometer/odometer for enduro's and street use. I'm vascillating between the above, and this one:

As you can tell, my requirements revolve mostly around cost as building a bike from scratch is

Jays100

Veteran Member

Still brazing motor mounts. I have a TIG welder but as this frame was brazed, I resurrected an old BernzOmatic rig. It uses Mapp gas and Oxygen cylinders. The oxy cylinders are low, low pressure and don't last long so I've had to re-order at the 1/2 way point.

My other dilemma is finding a vapor blaster or building one. the local services do good work but they're horribly expensive.....over $150 for just engine cases. Of course I need every surface blasted so thats a no-go right off the bat. The aluminum is pretty gross and the sheer acerage needed to do by hand is daunting, also a no-go. what to do? are there total loss soda blasters?

My other dilemma is finding a vapor blaster or building one. the local services do good work but they're horribly expensive.....over $150 for just engine cases. Of course I need every surface blasted so thats a no-go right off the bat. The aluminum is pretty gross and the sheer acerage needed to do by hand is daunting, also a no-go. what to do? are there total loss soda blasters?

Wish I could offer some usable suggestions. I've never spent the dollars for any blasting, it's all expensive. I got some quotes to get my drag bike frame just sandblasted and it was outrageous, so I did the best I could with various drill attachments. But when it comes to corroded aluminum I know what you mean.