Another week of progress. Rebuild kit for the starter came in so started working on that. A few tricks I used for the starter rebuild. I used the little fiberglass tip of a touch up pen to clean the areas I needed to solder together

View attachment 18553

My next issue was how to hold everything in place while soldering. After about an hour of trying many different things I decided to use an old rubber joint that is off of the air cleaner cross over tube. It fit perfect to hold everything in place

View attachment 18554 View attachment 18555

With a bit of flux and solder problem fixed

View attachment 18556

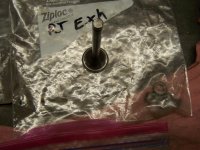

Everything was cleaned up. New bushings (the kit I got had the planetary gear bushings) all new seals and o-rings fresh grease. Painted the case parts and new screws

View attachment 18557

Bench tested it and it tried to jump off the bench.