-

Don't overlook our Welcome Package, it contains many links to important and helpful information about functions at VHT like posting pictures and sending PMs (private messages), as well as finding the parts you need.

AD

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bogging and backfiring at 6k

- Thread starter Avery_74cb360

- Start date

stl360+450

Veteran Member

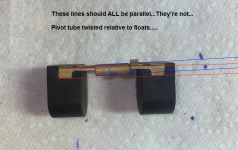

I don't know what else to say.......

Good eyes, Steve.

Good eyes, Steve.

Which is what makes Steve the Sensei.

Avery_74cb360

Veteran Member

Yes thanks you steve, that’s exactly what i was thinking when i saw them, but i was afraid i’d mess it up more trying to bend it the right way

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Avery_74cb360

Veteran Member

I think i’ve got it straightened out now. I’ll rig up a little test area and verify

Sent from my iPhone using Tapatalk

The worry is that the floats will/could somehow touch/rub against the inside of the bowl and "wedge"/drag enough to not rise fully and shut-off the fuel....

Not to mention that it makes it inordinately difficult to properly set float levels.....

Not to mention that it makes it inordinately difficult to properly set float levels.....

Avery_74cb360

Veteran Member

Gas is not coming out of the tank now? I tested it with it off the bike, and it didn’t leak. Put everything on the bike, and it’s not coming out of the tank, reserve OR on

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

How's the fuel level in the tank?

Avery_74cb360

Veteran Member

Full, save for maybe 1/3 gallon. It’s the carbs, took hoses off and it’ll flow with them off, so not the petcock. I saw on some forums for different bikes that it could be a clogged overflow valve? It’s odd because i JUST tested it with the carbs off the bike

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

And how do you know that no gas is going to the carbs? Did you loosen a drain screw on one of the bowls to check for flow? Or are you using translucent fuel line?

Avery_74cb360

Veteran Member

Translucent fuel line. That’s why i wanted them, to be sure the gas was going to the carbs. They were full anyways from when i tested it. I’m draining them now. I wonder if i don’t need to take the whole carbs off, the overflow valves are connected to the bowls anyways

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

Did you try loosening a drain screw to check whether any fuel reached the bowls? It would be strange for the vent to get plugged up when it had been working okay very recently.

It's possible that one of the float needles is sticking, but unlikely that both would be sticking right after putting everything together.

It's possible that one of the float needles is sticking, but unlikely that both would be sticking right after putting everything together.

Avery_74cb360

Veteran Member

Yeah the bowls seemed full, i waited a while when i was testing them to see if it would overflow, so they should have been full. Would fuel just not flow at all if they were? I would think it would go down to the carbs but not go in. Maybe i didn’t need to take the bowls off at all and it was actually fine

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

Sounds like all was well. The drain screws give you an easy way to check for fuel in the bowls. Ready to try starting it up again?

Yeah the bowls seemed full, i waited a while when i was testing them to see if it would overflow, so they should have been full. Would fuel just not flow at all if they were? I would think it would go down to the carbs but not go in. Maybe i didn’t need to take the bowls off at all and it was actually fine

Sent from my iPhone using Tapatalk

When the bowls are full there is no space for more fuel to fill the lines completely, so if you put the tank back on and the carbs are already full, for example, then visually it won't show any movement.

Avery_74cb360

Veteran Member

Well gee, if only i had my aha moment of basic physics BEFORE i left for a little family reunion i could have checked if it runs. Oh well, no big deal, sunday is always a big motorcycle shop day lol. I did end up taking the bowls off with a screwdriver ratchet attachment, so i was in the middle of putting the last one on before i left

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Avery_74cb360

Veteran Member

Wonderful news, after getting the bowls back on and cleaning out the overflow valves, the float must not be working anymore because it’s still flowing out of the hose. Not sure what changed from yesterday, but i suppose it’s round 7 taking the whole bike apart to get the carbs off

Update: Going to try to take the right float needle seat out, here’s a picture

It’s not bad or anything, but not nearly as shiny and clean as the left one, or the replacement i’ll put in

Not an original keihin part or anything, just something in the chinese rebuild kit the PO gave me, but a lot better than nothing

Maybe i should try to take the two pressure fit jet things out as well, the two that the slide interacts with i think it’s the emulsifier and something else. If you remember, i tried to do that once before but it got stuck, so i had to push it back in

Sent from my iPhone using Tapatalk

Update: Going to try to take the right float needle seat out, here’s a picture

It’s not bad or anything, but not nearly as shiny and clean as the left one, or the replacement i’ll put in

Not an original keihin part or anything, just something in the chinese rebuild kit the PO gave me, but a lot better than nothing

Maybe i should try to take the two pressure fit jet things out as well, the two that the slide interacts with i think it’s the emulsifier and something else. If you remember, i tried to do that once before but it got stuck, so i had to push it back in

Sent from my iPhone using Tapatalk

ballbearian

Veteran Member

You don't need the air filters or throttle installed to check float function. That seat doesn't look that bad, I've had luck just changing the little needle (with the springy end).

Avery_74cb360

Veteran Member

I guess the seat must have been the problem idk. Tested it with them off the bike, no overflow. Put them on the bike (no filters electronics or throttle) and they didn’t overflow there either. I didn’t adjust the floats again all i did was put the new seat in

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

ballbearian

Veteran Member

Before you reassemble more, see if you are getting proper and consistent levels in both bowls. should be just below the rims of the bowls.

If anyone has an actual bowl level spec. I'd like to know it too.

If anyone has an actual bowl level spec. I'd like to know it too.

Avery_74cb360

Veteran Member

Alrighty people, thank the lord we have victory. She fired right up, not a drop has come out of the overflow tubes. Started pretty high rpm, i got scared i thought it’d take off on me again if you remember from my other thread. Adjusted the throttle screw and it was perfect.

I mentioned in some thread, i can’t remember which, that the bike smelled a lot like gas. That was one of the first indicators here that it was running too rich. I don’t know how to explain it, but it smells more like a motorcycle now? Na less like gas?

Didn’t idle it for very long, it’s 10 o clock here. If i get out before the rain, i can test for bogging and backfiring tomorrow

Sent from my iPhone using Tapatalk

I mentioned in some thread, i can’t remember which, that the bike smelled a lot like gas. That was one of the first indicators here that it was running too rich. I don’t know how to explain it, but it smells more like a motorcycle now? Na less like gas?

Didn’t idle it for very long, it’s 10 o clock here. If i get out before the rain, i can test for bogging and backfiring tomorrow

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

Good progress. Let's see if it holds up in the morning - make sure that petcock is off. No point tempting fate, now or ever.

The fact that the idle was high initially still makes me wonder if it was running on one cylinder before and giving the occasional bang or pop from the other side. Hopefully you'll have two cylinders working together this time around.

The fact that the idle was high initially still makes me wonder if it was running on one cylinder before and giving the occasional bang or pop from the other side. Hopefully you'll have two cylinders working together this time around.

Avery_74cb360

Veteran Member

I always turn my petcock off! And lots of times forgot to turn it back on haha!

Yeah it’s odd, lots of times i start it the idle will be that high, other times it isn’t. I always blame it on having to adjust the idle speed once it’s warmed up. ALSO, when it would run rich it wants to die out at a stop, so i’d have to adjust it there sometimes i’m sure that was the fault a few times

Sent from my iPhone using Tapatalk

Yeah it’s odd, lots of times i start it the idle will be that high, other times it isn’t. I always blame it on having to adjust the idle speed once it’s warmed up. ALSO, when it would run rich it wants to die out at a stop, so i’d have to adjust it there sometimes i’m sure that was the fault a few times

Sent from my iPhone using Tapatalk

Avery_74cb360

Veteran Member

Well, the problem is still here. Got drizzled on a little bit for a quick run down the street and back but it didn’t get too wet. Still won’t go past 5.5-6k rpm, and backfires when i try to

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

The first video you posted about this seemed like you were trying to avoid reproducing the symptoms by gently applying the throttle. It would help to hear what it's doing when you try to ride it normally. And do these symptoms occur on the center stand in neutral or only while riding it? And can you confirm whether it's running on one or two cylinders? For example, if you keep the rpm below 5k does it ride perfectly normally or feel under powered or something else?

Avery_74cb360

Veteran Member

Good idea, i’ll let it warm up a second and then try it in neutral on the center stand.

It feels how it’s always felt to me when i kept it under 5k. Wether that’s both cylinders or not i don’t “know” but i’m fairly confident it is

Sent from my iPhone using Tapatalk

It feels how it’s always felt to me when i kept it under 5k. Wether that’s both cylinders or not i don’t “know” but i’m fairly confident it is

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

Try it with the air filters removed as well and watch to see if the slides rise when you have the rpm at or above 5k. Don't keep the rpm high for very long -- a few seconds at a time should let you know what's going on. If that do rise, are they dropping back down when you go back to idle?

I believe you have cleaned the slides, right?

I believe you have cleaned the slides, right?

Avery_74cb360

Veteran Member

Yeah i have, they were probably the cleanest part of the bike anyways. They’ve always come in and out easy but i’ll definitely be checking. Someone said to blow in it and the slide will rise, but i couldn’t get it right to check

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Avery_74cb360

Veteran Member

So yes it does still do it in neutral, albeit just slightly higher in rpms

Here’s a clip for the sound of the engine. Strapped my phone to the rear of the frame by the twilight so it’s much easier to hear

https://youtube.com/shorts/JdUa4eXMM4s?feature=share

At first i was confused, i’m first gear it didn’t big until about 7k rpm, so i thought the problem was gone but the same things happened once i reached that, then second gear was the same as usual

Sent from my iPhone using Tapatalk

Here’s a clip for the sound of the engine. Strapped my phone to the rear of the frame by the twilight so it’s much easier to hear

https://youtube.com/shorts/JdUa4eXMM4s?feature=share

At first i was confused, i’m first gear it didn’t big until about 7k rpm, so i thought the problem was gone but the same things happened once i reached that, then second gear was the same as usual

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

I didn't hear any backfire. And it sounded sluggish, but didn't really bog down noticeably for me. I'm still not convinced it's running on both cylinders, but I may be completely wrong. Were you riding normally? Seemed like a very slow climb in rpm. At idle, you feel equal back pressure on both pipes? And equal temperature?

What about checking the slides with the filters off while running it in neutral on the center stand?

What about checking the slides with the filters off while running it in neutral on the center stand?

Avery_74cb360

Veteran Member

Am i just not using the right words? I wish i had a video of the tach, everything climbs normally until 6k, then the bike and the needle just stops, needle flutters back and forth but doesn’t continue.

I can take the filters off and check, they’re just an absolute pain to get back on, the battery box has to come off to fit them all the way on

Sent from my iPhone using Tapatalk

I can take the filters off and check, they’re just an absolute pain to get back on, the battery box has to come off to fit them all the way on

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

I listened to it again and it does sound off at the higher RPM. I would say that it seems to momentarily "cut out" at high RPMs. Could be fuel starvation (bowls getting too low). Let's see what others say after they give it a listen.

Avery_74cb360

Veteran Member

I listened to it again and it does sound off at the higher RPM. I would say that it seems to momentarily "cut out" at high RPMs. Could be fuel starvation (bowls getting too low). Let's see what others say after they give it a listen.

Okay that sounds good. Here is another angle to view

https://youtu.be/A5l092C50MA

I swear i’m not crazy, but what i hear and feel is very obvious but doesn’t come across well on camera. Or maybe i am who knows

Sent from my iPhone using Tapatalk

Avery_74cb360

Veteran Member

Wait a minute, could the problem be a bad condenser??? I saw a couple places on the internet that it could lead to the same problem i’m having. And on top of that, it would explain why (if) one cylinder isn’t firing. The condenser i have was attached to the custom coil mounts on the bike when i got it. It had no connectors and wasn’t in use, pamco system doesn’t need it.

How can i check if the condenser is working?? I have a spare from an old set of my dads coils, but i doubt it would work.

Sent from my iPhone using Tapatalk

How can i check if the condenser is working?? I have a spare from an old set of my dads coils, but i doubt it would work.

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

If you'd like to check: try running it tonight when it's a little darker and check to see if either of your points is sparking excessively. Small, occasional sparks would not be unusual.

You could remove the condensers and measure capacitance from one lead to the body. It should be 0.22-0.33 micro Farads, based on the 350 FSM.

You could remove the condensers and measure capacitance from one lead to the body. It should be 0.22-0.33 micro Farads, based on the 350 FSM.

Avery_74cb360

Veteran Member

If you'd like to check: try running it tonight when it's a little darker and check to see if either of your points is sparking excessively. Small, occasional sparks would not be unusual.

You could remove the condensers and measure capacitance from one lead to the body. It should be 0.22-0.33 micro Farads, based on the 350 FSM.

Okay cool, will do. Is micro farad the little uF symbol? I can check my old condenser right now.

Not sure which one of these would measure that

Sent from my iPhone using Tapatalk

Avery_74cb360

Veteran Member

Damn, i’m not sure what “excessive spark” really looks like, but given the left one has nothing close to what the right one has, i’m gonna go out on a whim and say bad condenser

https://youtube.com/shorts/3Opnli2IVuw?feature=share

Sent from my iPhone using Tapatalk

https://youtube.com/shorts/3Opnli2IVuw?feature=share

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

Avery_74cb360

Veteran Member

Yeah i figured it couldn’t. Should i buy a new meter or does the video tell you enough?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

You could switch the leads on the condenser to see if the left side starts to spark more than the right. The condenser wires are color coded, but that's not important -- I think it's just supposed to help you remember where to plug in the points leads (which does matter).

Avery_74cb360

Veteran Member

I saw that on common motor surprisingly. I reeeeeally didn’t want to take the tank off the check but i definitely will

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

stl360+450

Veteran Member

You might be able to swap the wires without removing the tank completely. Just lift it up a bit to access the condenser wires. Draining the tank is a pain.

Edit: I forgot you don't need to drain the tank on a 360 -- no crossover tube.

Edit: I forgot you don't need to drain the tank on a 360 -- no crossover tube.

Avery_74cb360

Veteran Member

No i can’t, I have the wires tucked up high zip tied lightly together so they didn’t hang down everywhere. It’s not completely full anymore so it’s not gonna be AS heavy as it was haha

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

You could cheat a little and slide the tank back off the rubber mounts in the front, then lift the front of it up and put something like a block of wood in between the tunnel and the top of the frame to give you enough clearance to work without fully removing the tank.

ballbearian

Veteran Member

As much time and money you've spent. My gut says your timing is off on one cylinder, at least.

If I were you, I'd get a stroboscopic timing light and check on both cylinders.

Amazon.com: ROADGIVE 12V Engine Timing Light Strobe Lamp Inductive Petrol Ignition Timing Light Automotive Tool with Spark Plug Tester for Car Motorcycle Marine Lawnmower : Automotive

If I were you, I'd get a stroboscopic timing light and check on both cylinders.

Amazon.com: ROADGIVE 12V Engine Timing Light Strobe Lamp Inductive Petrol Ignition Timing Light Automotive Tool with Spark Plug Tester for Car Motorcycle Marine Lawnmower : Automotive

Avery_74cb360

Veteran Member

Went through gap and the timing again. Everything was slightly off, so i thought that would have fixed it. Stops at about 5k rpm now instead of 6-7k.

When it cools off i can check on the point spark again. Actually when i fired it up this morning before i adjusting timing, i didn’t see much spark on the right and no spark on the left.

Sent from my iPhone using Tapatalk

When it cools off i can check on the point spark again. Actually when i fired it up this morning before i adjusting timing, i didn’t see much spark on the right and no spark on the left.

Sent from my iPhone using Tapatalk

ballbearian

Veteran Member

Tiny points spark is actually normal. It can be hard to see in bright light.

Sounds like you rotated the points plate to adjust the timing and that changes the timing for both points (cylinders) when you do that. I found it easier to move the points on the plate, rather than move the plate because of that. This is also why CMC showed filing the slots on the points so they could be moved enough to achieve both points at correct timing.

Again, a timing strobe light can make your life easier with this and also know that your advance curve is correct.

Sounds like you rotated the points plate to adjust the timing and that changes the timing for both points (cylinders) when you do that. I found it easier to move the points on the plate, rather than move the plate because of that. This is also why CMC showed filing the slots on the points so they could be moved enough to achieve both points at correct timing.

Again, a timing strobe light can make your life easier with this and also know that your advance curve is correct.

Avery_74cb360

Veteran Member

I’m considering changing my ignition system back to the stock platform.

This is the setup now, with custom bracket made for these coils

It’s not made for use with a condenser, they were changed to work with an electronic ignition system.

I’ve got a spare set (2 actually) of stock coils and wires. Yellow one reads 5.0 and blue reads 4.6. I don’t think you can check the wires with these correct? But they should be good otherwise i’m assuming. I want to go to these so that one: i know the new condenser will be properly grounded, and two: the ground from the harness being better grounded with sturdier brackets.

Right now i’m going through carbs again, got the emulsifier tubes out for the first time, and i’ll try to learn how to clean off the slides.

Let me know what your thoughts on this are

Sent from my iPhone using Tapatalk

This is the setup now, with custom bracket made for these coils

It’s not made for use with a condenser, they were changed to work with an electronic ignition system.

I’ve got a spare set (2 actually) of stock coils and wires. Yellow one reads 5.0 and blue reads 4.6. I don’t think you can check the wires with these correct? But they should be good otherwise i’m assuming. I want to go to these so that one: i know the new condenser will be properly grounded, and two: the ground from the harness being better grounded with sturdier brackets.

Right now i’m going through carbs again, got the emulsifier tubes out for the first time, and i’ll try to learn how to clean off the slides.

Let me know what your thoughts on this are

Sent from my iPhone using Tapatalk

#1....The coil brackets/cores themselves DO NOT need to be grounded, and you CAN check the secondary windings and plug wires with your meter.....

(The points ground the primary windings, the sparkplug provides ground for the secondary... That's how they work....)

#2.... The condensers DO need to be grounded, but any connection on a rusty area is at best "iffy".....Clean the contact area to bright shiny metal....

As always, you may phone for clarification.......

(The points ground the primary windings, the sparkplug provides ground for the secondary... That's how they work....)

#2.... The condensers DO need to be grounded, but any connection on a rusty area is at best "iffy".....Clean the contact area to bright shiny metal....

As always, you may phone for clarification.......

Avery_74cb360

Veteran Member

#1....The coil brackets/cores themselves DO NOT need to be grounded, and you CAN check the secondary windings and plug wires with your meter.....

(The points ground the primary windings, the sparkplug provides ground for the secondary... That's how they work....)

#2.... The condensers DO need to be grounded, but any connection on a rusty area is at best "iffy".....Clean the contact area to bright shiny metal....

Sorry i must have worded it confusing. I did not mean the coils need grounded, but the main ground that comes off of the harness that grounds between the brackets. The metal on the frame I sanded down to get good contact, but the custom brackets come a little loose sometimes.

How can I check the plug wires on those original coils? If both those readings are okay, then that should be the only thing i need to check