jensen

Veteran Member

The build of The Three Twins (CB450's, maybe 4), an inquiry into Differences and Similarities

Hi,

As a long time member of the HondaTwins forum I only started a few threads over the years, so I thought, it's time to start another one.

In this thread I will build three, or maybe four CB450's at once. It will take many months, if not years, so if you're expecting a quick read, skip this one. If I start a thread I do it thoroughly, no shortcut's here.

Over the years I acquired a lot of CB450 bikes and parts and stashed them in boxes and crates. Actually, after 20 years of collecting, (or hoarding) it's a huge amount of parts. I could build many bikes from those parts, and that's exactly what I'm gonna do, but let's start moderate and start with four:

The bikes I want to build are :

I will mainly concentrate on differences between the parts used in these bikes, and when I say parts, I mean all parts. From cam followers to mudguards, every part will be examined and compared within the bike types. I hope that people chime in to comment or to point out errors in my assumptions. I would appreciate that questions or comments are related to this thread and not to ask questions about your own bike or issue's with your bike.

Here are the pictures of the bikes I start with, the K0 is a picture from a folder, since I acquired only parts, and not a complete bike. There should be at least 3 bikes in the K0 parts though.

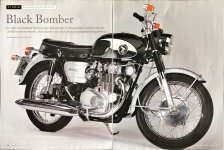

The CB450 K0 as it should look like when it's finished:

Here a picture of the CB450 K1, early Dutch version, which I also got in boxes, but the owner had a picture of the bike and I made a scan from that picture:

A picture of the CB450 K1, early US version, which also came in boxes:

And last but not least, a picture of the CB450 K2, US version:

Although it seems that the bikes (except the CB450 K0) are more or less the same, the amount of differences are huge. Many parts are different, sometimes in an obvious way, sometimes in a very detailed way.

The first thing I'm gonna do is to dive into the engine parts. At the moment I'm in the process of classifying engine parts only, it's a huge job since I have many parts. In the process of cleaning, measuring and classifying I noticed many (small) differences in parts and it's clear that Honda improved parts over the years.

This thread will mainly focus on all these (small) differences.

btw, don't expect an weekly update. I have a busy job (R&D manager), two sons and a wife (not necessary in that order of importance).

Hi,

As a long time member of the HondaTwins forum I only started a few threads over the years, so I thought, it's time to start another one.

In this thread I will build three, or maybe four CB450's at once. It will take many months, if not years, so if you're expecting a quick read, skip this one. If I start a thread I do it thoroughly, no shortcut's here.

Over the years I acquired a lot of CB450 bikes and parts and stashed them in boxes and crates. Actually, after 20 years of collecting, (or hoarding) it's a huge amount of parts. I could build many bikes from those parts, and that's exactly what I'm gonna do, but let's start moderate and start with four:

The bikes I want to build are :

- CB450 K0, 1966, a Dutch / German version

- CB450 K1, 1968, an early Dutch / German version

- CB450 K1, 1968, an early US version

- CB450 K2. 1970, an early US version

I will mainly concentrate on differences between the parts used in these bikes, and when I say parts, I mean all parts. From cam followers to mudguards, every part will be examined and compared within the bike types. I hope that people chime in to comment or to point out errors in my assumptions. I would appreciate that questions or comments are related to this thread and not to ask questions about your own bike or issue's with your bike.

Here are the pictures of the bikes I start with, the K0 is a picture from a folder, since I acquired only parts, and not a complete bike. There should be at least 3 bikes in the K0 parts though.

The CB450 K0 as it should look like when it's finished:

Here a picture of the CB450 K1, early Dutch version, which I also got in boxes, but the owner had a picture of the bike and I made a scan from that picture:

A picture of the CB450 K1, early US version, which also came in boxes:

And last but not least, a picture of the CB450 K2, US version:

Although it seems that the bikes (except the CB450 K0) are more or less the same, the amount of differences are huge. Many parts are different, sometimes in an obvious way, sometimes in a very detailed way.

The first thing I'm gonna do is to dive into the engine parts. At the moment I'm in the process of classifying engine parts only, it's a huge job since I have many parts. In the process of cleaning, measuring and classifying I noticed many (small) differences in parts and it's clear that Honda improved parts over the years.

This thread will mainly focus on all these (small) differences.

btw, don't expect an weekly update. I have a busy job (R&D manager), two sons and a wife (not necessary in that order of importance).

Last edited: